Enzymes: A Love Story

- Scientific Articles

Enzymes have been our friends for millennia, they’ve helped us eat better food, drink nicer drinks, clothe ourselves in more robust materials and, thanks to modern technology, mass produce to our hearts content. We have a lot to thank enzymes for.

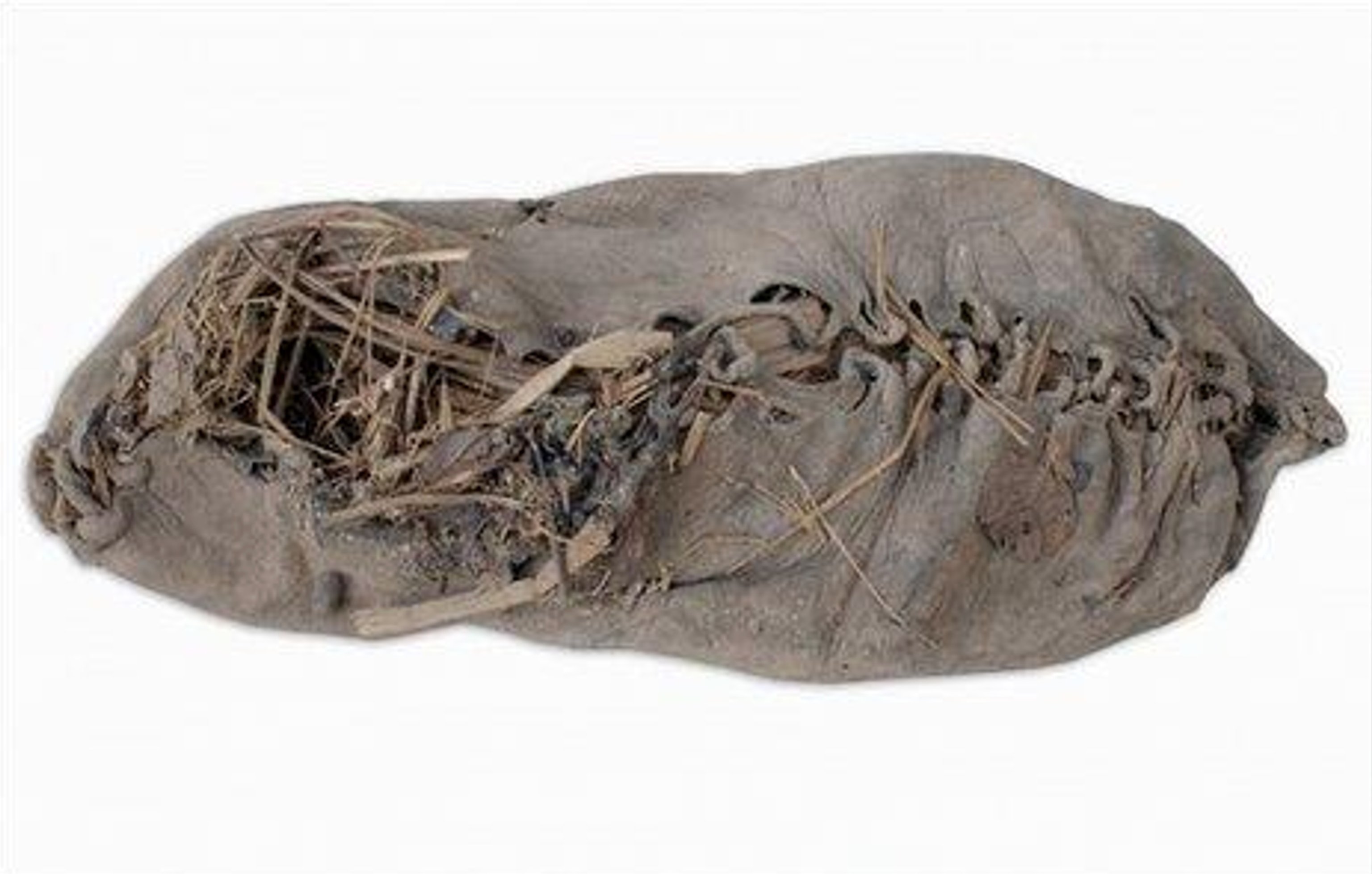

It all started around 7000 BC when the Chinese discovered how to ferment rice, honey and hawthorn fruit to make alcohol. The process of fermentation went on to bring us leather products around 3500 BC, the first cheeses around 2000 BC and yeast-baked bread around 1500 BC. In all these cases, people were using microorganisms to perform chemical reactions. And how did we do it? By using enzymes.

Oldest leather shoe dating back to 3500 BC, discovered in Armenia. Credit: BBC News

Skip forward a millennia or two and enzymes had become a fixture in global industry. Rennet (a cocktail of microbes capable of coagulating milk) was used to standardise cheese production in the 1860s. Yeast fermentation produced thousands of tonnes of glycerol for Germany during WW1. Citric acid was being mass produced across the globe using the fungus Aspergillus niger (The US alone made almost 12 million kg per year by 1949!). Glycerol and citric acid are key components in medications, cleaning products, cosmetic agents and food sweeteners.

There are many more examples of enzyme-facilitated mass production during this time, all reliant on enzymes within microbes. This worked fine for a while, but the need to keep microbes alive meant that industrial output was always limited. That was until the 1950s when scientists learned how to isolate enzymes, and by doing so, took mass production to the next level.

The Enzyme Revolution

Instead of having to grow, culture and nurture microbes for their enzymes (which takes a lot of time and energy) scientists found ways to isolate and immobilise enzymes. This meant that one batch of enzymes could be used and reused, skyrocketing the efficiency of mass production.

In 1957 high fructose corn syrup (HFCS) was created using immobilised glucose isomerase to ferment corn starch. By side-stepping the need to use pure corn and beetroot sugar, food production became a lot cheaper. 1975 saw the first instances of HFCS being used in the food industry, but nowadays, it can be found in nearly all packaged food and drink.

But food wasn’t the only thing to change in the face of immobilised enzymes. Penicillin acylase was first discovered in 1950 for its ability to make aminopenicillanic acid, the main component in a variety of antibiotics; it's now responsible for a $15 billion industry.

Antibiotic medications. Credit: SkyNews

Over the next few decades enzymes found their way into pretty much everything. Many modern detergents use enzymes to facilitate the reaction between laundry soap and grime, yup we have enzymes to thank for our stainless clothes and clean dishes. Lactase is used to make lactose free milk, catalase is used to preserve food while glucose oxidase and peroxidase are used to improve the flavour and appearance of food products (and the list goes on).

So there you have it, our age old enzymatic love affair. Enzymes currently make trillions of dollars per year across a multitude of industries. They feed us, make our medicines, clean our dishes and… break down our plastic?

Why Do We Love Enzymes?

Samsara Eco’s scientists have designed enzymes capable of solving one of the largest environmental problems of the modern age: plastic waste pollution. Our enzymes are able to break plastic back down into its core chemical building blocks without any deterioration, meaning it can be recycled infinitely to build brand-new, high-quality products. This feat has previously been impossible due to traditional recycling methods, read our ‘traditional recycling = downcycling’ article to find out why.

Plastic landfill. Credit: Science News.

By harnessing enzymes, Samsara Eco is revolutionising plastic recycling. With our EosEco technology we can STOP producing more and more virgin plastic from damaging fossil fuels and instead start using what we already have – without sacrificing its quality. Enzymes are not only industrial superpowers, they are our plastic-fighting heroes.